..........................................................................................................................................................................................................

motorex lubricants and cleaning sprays

it has become definably colder and wetter over the past few days, and as i write from my idyllic hidey-hole on the edge of the atlantic (artistic licence; the atlantic is at least 14 miles away), i can hear the wind wrapping itself round most of the bushes outside, and having a darned good shot at making its way in through the open window. i believe that one of the weathermen on tv the other day defined the incoming as autumnal, though as a relative term, this obviously exists in varying degrees according to one's personal insulation.

as a small agricultural nation, there has also been a noted upsurge in the amount of (i'm being polite here) agricultural effluent decorating the almost road surfaces, due to the accepted notion that islay cattle are free to roam wherever they deem suitable. i have become inured to the wearing of mudguards on both the colnago and the cielo, for while it may present a serious dent to one's street credibility, it has the happy consequence of keeping the aforementioned effluent away from a pair of bright yellow mavic shoes. and, likely of more note, away from the inner an outer reaches of either frame. such freedom from concern can be yours too, if you'd care to place some roadracers on that team sky replica dogma.

however, even a decent set of fenders cannot exclude all the gunk that accumulates on anyone's road surfaces, let alone the ones on islay, and it's a sad but true fact that it's all too easy to simply pop the still wet and dirty bicycle into the bike shed on arrival at basecamp. it would do the heart and soul great favour if we were to take a few moments to wipe down frame, components and wheels prior to stowage, but since we are likely in a similar state of disrepair ourselves, it's a task that is either forgotten, ignored or both. those few moments, accumulated over time, will come back to haunt you, as they have often do so to me.

while it is possible to purchase bicycle chains in black, silver, gold and, in extreme cases of spending, titanium, i have seen none on general offer that are either orange or a dark reddish brown. yet that's often the sight that meets the less than fastidious cyclist, resplendent in sparkly sportwool as the shed door is opened. it's a situation that can occur at anytime of the year, quite frankly, but has a greater chance of being the case as autumn and winter approaches, and it therefore behoves the conscientious amongst us to practice a smidgeon of preventative care.

there are as many oils and lubricants on the market as there are different carbon frames, and short of various biological and mechanical tests carried out with infinite precision, it is an onerous task to separate the men from the boys. and really, what is the difference between a dry-lube and a wet one, given that they're both wet at the point of application? motorex of switzerland, perhaps better known for applications within the motorbike world, provide a veritable slew of products pertaining to two wheels and a pair of pedals. i have had the opportunity to experience a number of these, some of which are very pragmatically contained within a handled, plastic tub; a small bottle of dry-lube, a can of chain degreaser, spray-on bicycle cleaner, a sponge and a drying cloth. additionally, i have a can of bike shine and a bottle of wet lube.

i would be happy, at this point, to inform you as to which of the lubes is the better option, having applied the dry lube to the colnago, and the wet lube to the sram chain on the cielo. however, neither have experienced enough of the wet stuff to provide the definitive answer, so at some point in the future i'll feature a head to head. meantime, the only visual difference is the whiteness of the dry, and the oily clarity of the wet. both can be applied with ease to one link at a time by means of the application nozzle incorporated in each lid, and are of a viscosity that almost encourages a substantial number of drips on the ground. do not carry this out on the sitting room floor.

even on new, straight-out-of-the-packet chains, there are vestiges of grease; in order to test these motorex synthetic lubricants that can of degreaser came in very handy, cleaning both chains within an inch of their lives before applying the respective lubricants. this was my attempt to be squeaky clean (did you see what i did there?) and ensure any effect on the chains was via the motorex and not remnants of whatever i had on before. i have great preference for the economy of these small applicators as opposed to the spray cans which seem to lubricate every stationary object within a 15 mile radius.

meantime, of more pressing need/desire, is the necessity to have that paintwork shiny and standing to attention, which is where the cleaning kit comes into its own. the motorex bike clean does what it says in the canister, aiming a fine spray all over every nook and cranny prior to the grunt work. leaving the spray in place for around five minutes loosens pretty much every dirt particle and allows it to be effortlessly wiped away with the supplied sponge and the bucket filled with warm water. and i really mean effortlessly. the cloth provides the wherewithal to effect a semblance of drying, prior to scooting the whole bicycle with delicate sprays of bike shine, leaving to dry(ish) before a modicum of elbow grease polishes all to a distractingly shiny finish.

the worst part about all this is the fact that it really takes so little time, that it renders all excuses for not doing it completely redundant. all that remained was to empty the bucket of the now dirty water, plop the constituent parts back inside, snap on the lid, and all is ready for next time.

and that won't be long in coming.

posted tuesday 13 september 2010

..........................................................................................................................................................................................................colnago master x-light carbon

it would be a foolish cyclist who denied that steel, the perennial frame material, has not enjoyed somewhat of a resurgence in recent years. some of this is undoubtedly due at least in part, to north america, and perhaps more specifically, portland, oregon. for while much of europe has cast aside its heritage for carbon, many one man frameshops in the usa have welcomed this versatile material with open brazing rods. my good friend richard sachs has had a lengthy career building bicycles using no other frame material. he is nothing if not dogged in his choice of material, and with good reason, both from the point of view of construction and the quality of ride.

colnago have produced the master frameset and its various derivatives for the past 30 years, and are one of only a handful of italian framebuilders still offering steel as part of their range. the current model is the master x-light constructed from lugged steel, front to back. unless of course it's the master x-light that currently resides in thewashingmachinepost bikeshed.

this one differs from the mainstream by featuring a carbon b-stay rear end, though the molteni colour scheme cunningly conceals this melding of one material with another. it's taken me way too long to build this bike up, but now that such has been accomplished, does the frame that once sat at the top of the colnago range, still cut the mustard, so to speak? and perhaps more to the point, is it a good idea to stick carbon on the back end?

find out here.

molteni cap courtesy of prendas, from where a matching jersey can be obtained posted monday 13 september 2010 wheelnuts. it's not the most attractive word in the english language, and if applied as a nickname, hardly likely to be the most complimentary either. but in terms of its application to the bicycles of yesteryear, a particularly adept solution to affixing a pair of wheels to the frame. that is, unless you happened to be tullio campagnolo and have your fingers so frozen as you attempted to cross the croce d'aune pass (why do campagnolo not revive a that as a groupset name? so much more attractive than centaur.) that the wingnuts were beyond loosening. i doubt whether tullio thought it the finest appellation at that particular moment either, though he would have cursed the italian equivalent. thus, assuming you are steeped in the lore of cycling's heritage, was the quick release lever born, needing only a smidgeon of grip and effort to open and drop the wheel from the dropouts. this is a process that has been vastly aided vis-a-vis the rear wheel by the almost wholesale change from road style horizontal dropouts to the vertical variation first seen on those mountain bikes that we all detest (well, we don't really, but it is unseemly to admit otherwise in polite

the latter is just one example of american litigiousness gone barmy. it's perhaps not unreasonable to expect this level of health and safety on entry to mid-level cycles, but surely anyone in the market for such as a colnago c59 would have the gumption to make sure the q/r is properly shut? i have, in the past, queried various authorities on the enforcement of this method of turning a quick release into the equivalent of a wingnut, but there seems no consistency in its application. all of colnago's current carbon production features these fork tabs, yet the steel precisa fork on the master frames do not. and likewise the steel fork on the chris king cielo; on my particular example, there are no tabs, yet this is a frame built in portland, oregon. go figure. however, quick release skewers have been through many a variation since the original campagnolo version of yesteryear, but basically, all work on the same principle; a cam in the lever side pulls the skewer, clamping the forks against the wheel locknuts. it's a robust system, for i have come across several that have completed their alotted task despite those pyramidal veloute springs being totally absent. however, i have also comes across, and very recently too, a skewer that is so corroded that it is not only impossible to release the tension, but unable to be unscrewed either, resulting in another job for the junior hacksaw. the problem there is the use of steel for the skewer; aluminium is really too soft for the job. a metal easily up to the task in terms of strength as well as corrosion resistance is titanium, gaining brownie points through its more than attractive metal sheen. titanium experts, van nicholas of holland, have recently produced a rather excellent minimalist pair of titanium quick release skewers

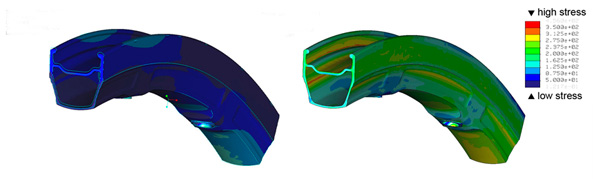

and were good looks not enough, a pair of these will barely move the marker on a set of kitchen scales, weighing a scant 64 grams (not much more than two ounces in old money) for only around £35, likely one of the best, low cost upgrades that could be applied to anyone's bicycle. purchasing can be effected online via the van nicholas website, and i'd respectfully suggest that you stop whatever it is you're doing (silly me. you're reading this aren't you?) and order a pair before you forget, then we can all be safe and stylish at the same time. in a word, fabulous. posted sunday 12 september 2010 it's no secret that those of the carbon persuasion who are now offering us carbon rims for our clincher tyres, had many a happy day scratching their heads in the research and development department, trying to figure out how to stop the tyres blowing the rims to pieces when up to pressure. aluminium rims cope with these sort of pressures really well, or at least a lot better than carbon, the latter being particularly brittle unless suitably reinforced in the appropriate vector plane. the recently tested carbonsports lightweight clinchers featured a large warning sticker on the rim against inflating beyond 8 bar for that very reason. we pretty much take it for granted that popping any clincher on any aluminium rim is technical simplicity itself, always assuming that the tyre slips on easily in the first place. i know i'm not the only one who has come across a more than recalcitrant example which refuses point blank to go those extra few centimetres and slide over the rim bead, leaving a trail of broken tyre levers and very sore thumbs in its wake. however, this incompatibility (almost) with carbon should perhaps have alerted us all to the fact that sweetness and light were mere fractions away from all out war twixt hoop and tyre (i exaggerate, but only for the sake of excitement). mavic, they of the yellow following cars, have been making wheel rims since 1934, and it would ill behove any of us to doubt their veracity for creating some of the finest bicycle rims on the market today, and it is not likely that they got to where they are today without knowing a thing or two about how an inflated tyre and tube affects their products. whether the various tyre manufacturers study the same from the opposite side of the fence i know not. it was, perhaps, only a matter of time before mavic decided that the knowledge gained over those years would persuade them that they maybe knew enough to match a pair of tyres with rims; which, of course, is exactly what they have done with the recently released k10 system. the 23c tyres are almost featureless, in that they are solid black with no tread whatsoever, superficially similar, in fact, to a pair of schwalbe ultremos, but with a bit more texture to the tread. mavic denote this as griplink, a dual compound surface meaning a bit more elasticity and grip on the shoulder, and harder wearing in the centre. the only markings that identify either front or rear as being from mavic, are the red. white and yellow k10 logos on the sidewalls. if i understand the literature correctly, the tyres are apparently known as mavic yksion, but this is only referred to on the wheel rim and strangely not on the tyres. the wheels are a development of mavic's incredibly successful ksyrium series, with the weight reduced to a mere 1470 grams principally by machining excess metal from the side of the rim in panels just below the braking surface. the flat spoke count is predictably minimal at a mere 18 on the front wheel and 20 at the back, but strangely the rear is radially laced on the drive side and two cross on the non-drive, contrary to the notion that the former experiences greater stresses than the latter. the rear hub reassuringly features a very thick and heavily machined non-drive flange. the zicral flat bladed spokes are tensioned in the rim by splined spoke nipples which require a proprietary spoke wrench (supplied) should the wheel need truing. the wheels also arrive with the necessary tools to adjust the cones when a modest degree of play eventually arises. at least some of the weight loss must also have been achieved by exchanging the former ksyrium front alloy hub for a carbon fibre model, thus the front wheel tips the scales at a rather scant 638 grams, and the whole kit and caboodle, rims, tyres, tubes weighs only 2100 grams. it's interesting to compare weights such as these with today's state of the art carbon frames at under 1kg. the wheels arrived in two cardboard boxes complete with mavic logo'd wheelbags, skewers and the necessary bits and bobs to maintain them in the manner to which they are likely wont to become accustomed. helpfully, the tyres and tubes are already fitted at point of receipt, and it's a nice touch that the logos on the tyres are matched to the logos on the wheels. the rear supplied featured mavic's m10 freehub, splined to accept either shimano or sram cassettes. since these are currently fitted to a colnago master running campagnolo centaur, i fitted an american classic compatible cassette. additionally, for the time being i have eschewed the mavic supplied skewers, replacing them with a rather fabulous and minimal pair of corrosion free titanium skewers from van nicholas. (more about these in the coming days). i have perhaps made my point clear regarding the spoke count and lacing of so-called boutique wheels, in that i generally regard them with suspicion. are the spokes straight and radial because it makes it easier for machines to build them, or is there really a reputed advantage in so doing, and i am merely cynically inclined? in the case of mavic's k10 pairing, i fear it may be the latter, for these ride easily as well as many a handbuilt pair encountered over the years. there is no doubting their stiffness and aptitude for the job of riding very quickly;

the tyres are great. on a bicycle that positively encourages squiggly stuff on corners, descents and a combination of the two, the grip was marvellous, even on the sketchy, gravely stuff that inhabits the bits of road that you'd really rather it didn't. strangely, and rather contradictorily, when standing up to climb the occasional rough stuff on the hills, the back wheel provided a little hop, skip and a jump, suggesting that grip was being lost. however, these are not the only tyres that do this on our roads, so i'm not sure it's anything to be seriously concerned about; on smoother surfaces, grip was as exemplary as you'd expect. my theory, should you be interested, is that the lightness of the wheel is a contributory factor, but on a 75km ride it really only happened on a couple of occasions and the road surface didn't look like a billiard table. despite my having a higher in physics, i don't remember anything concerning pressures exerted on metallic structures, so despite mavic's pretty pictures on the website, i have to put my hand up and plead ignorance of such matters; the only tangible evidence available is the riding i've been doing for the last few weeks. on that basis, mavic are pretty much on the money with this pairing, a combination that has already been developed further with the recently announced 2011 range available early next year. meantime, if you're in the market for a pair of wheels that seem to do everything particularly well, on a wide variety of road surfaces, the k10 system should be at or near the top. recommended retail is around the £900 mark, but i have seen them offered recently for as little as £600. it's rather comforting to know that not only are mavic continuing their seemingly endless development, but that they have our very best interests at heart. posted saturday 11 september 2010 if you are, unlike me, a frequenter of the cycling forums, you may have come across postings under the pseudonym gottheteeshirt, a fine nom de plume for britain's finest ever grand tour contender, robert millar. for while robert has no wish to be found, and is apparently content living his life the way he wants to, he keeps his eye on the ball, so to speak, and has waded in where he feels it necessary so to do, just to keep all the wannabees, doubters and true fans on the straight and narrow. this has, if anything, increased robert's standing within the contemporary cycling community; the man still has a lot to say of value, making a change from some of the drivel that occupies many of the competing threads on cycling forums. he has also surfaced occasionally in recent issues of rouleur, and gave a fine tribute to his contemporary, the late laurent fignon on cyclingnews.com recently. so it really is little wonder that a great many of us still hold him in high esteem. it matters not one whit what robert is doing nowadays; he's the very guy who got hundreds, if not thousands into cycling and he is celebrated for his career achievements: king of the mountains in the tour, climber's jerseys in the vuelta and giro, and british national road champion. and even better, for some of us, he is scottish. last year i produced a jersey to celebrate the 25th anniversary of robert's king of the mountains jersey in 1984. this year someone else is intent on producing an i've gottheteeshirt t-shirt featuring drawn illustrations by neil reed, and taken from freely authorised photographs by graham watson. costing £20 plus £3 postage and packing, all the profits are being donated to the braveheart fund. it's robert's birthday on monday (13th september), and while it may take a whiley longer to have one of these delivered, it would be a nice gesture to order one and give robert a sort of birthday present with a difference. if you'd like to acquire something that will be a limited edition product that celebrates the career of britain and scotland's very best, send an e-mail to gettheteeshirt@aol.com, and payment details will be mailed as soon as all is finalised. remember, this is also benefiting scotland's braveheart fund. posted friday 10 september 2010

van nicholas titanium wheel skewers

company). despite this, i have great affection for road dropouts, though i can't for the life of me think why. the quick release skewer has also been confounded on the majority of bicycles, even those with serious professional credentials, by what are commonly referred to as lawyer's lips; little tabs cast into the front fork dropouts to prevent the front wheel falling out if the quick release hasn't been closed properly.

company). despite this, i have great affection for road dropouts, though i can't for the life of me think why. the quick release skewer has also been confounded on the majority of bicycles, even those with serious professional credentials, by what are commonly referred to as lawyer's lips; little tabs cast into the front fork dropouts to prevent the front wheel falling out if the quick release hasn't been closed properly.

which have been holding on to a pair of mavic ksyriums (ksyria?) for the past few weeks, not only carrying out their job with remarkable efficiency, but adding considerable aesthetic appeal for shiny items of such small stature. titanium has a reputation for the occasional creak and groan while going about its business, and despite a reassuring creak as the sculpted levers are forced shut, the van nicholas skewers have remained completely silent under duress.

which have been holding on to a pair of mavic ksyriums (ksyria?) for the past few weeks, not only carrying out their job with remarkable efficiency, but adding considerable aesthetic appeal for shiny items of such small stature. titanium has a reputation for the occasional creak and groan while going about its business, and despite a reassuring creak as the sculpted levers are forced shut, the van nicholas skewers have remained completely silent under duress.

mavic k10 wheel/tyre system

or at least as quickly as i can manage, but it is a mystery as to how comfortable they are when given a bit of a doing over a sequence of cattle grids and roads with a surface comparable to that of the sea of tranquility. i employed, yet again, my totally unscientific procedure of closing the rear brakes as much as i dare, popping the bicycle into the outer ring and pushing as hard as my little legs would carry me. the unscientific bit is the fact that this has almost as much to do with the frame's rear triangle as it is with the wheel itself, but in any case, i was unable to encourage any rubbing on the rear rim, thus mavic's drive side radial lacing must be the biz after all.

or at least as quickly as i can manage, but it is a mystery as to how comfortable they are when given a bit of a doing over a sequence of cattle grids and roads with a surface comparable to that of the sea of tranquility. i employed, yet again, my totally unscientific procedure of closing the rear brakes as much as i dare, popping the bicycle into the outer ring and pushing as hard as my little legs would carry me. the unscientific bit is the fact that this has almost as much to do with the frame's rear triangle as it is with the wheel itself, but in any case, i was unable to encourage any rubbing on the rear rim, thus mavic's drive side radial lacing must be the biz after all.

gottheteeshirt