..........................................................................................................................................................................................................

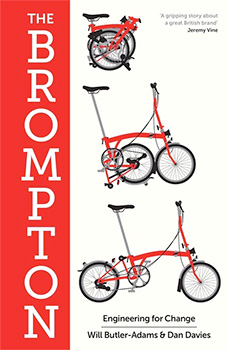

the brompton: engineering for change. will butler-adams & dan davies. profile books hardback. 278pp illus. £25

"Our philosophy demands the following: To offer only products which have real practical value, to avoid developments and designs whose primary appeal is superficial and unlikely to be genuinely useful."

an excerpt from the brompton company philosophy.

form follows function; a mantra either beloved of designers of all kinds everywhere, or one regarded with disdain. perhaps glaring examples of form that paid little attention to function, would be gothic architecture and 1950s american automobiles. on the other hand, to extend the motor car connection, the citroen 2cv and the volkswagen beetle are two in which form very definitely follows function. and though it pains me to write, cars raced in formula one, aside from their colour schemes also feature a form that follows function.

bicycles, by and large, at least until carbon fibre entered the fray, are entirely functional, a state of affairs that was punctuated only by the trend for ornate lugwork in the mid twentieth century. and even then, the function of the latter was to identify one marque against another. and i confess, it had never occurred to me that the iconic brompton folding bicycle was pretty much the epitome of the aforementioned mantra. it's one thing to make a statement as identified above, but a whole 'nuther bucket of hinges to stick to it in the face of changing trends.

the original brompton (named after brompton oratory which the inventor viewed through his kitchen window in knightsbridge) was conceived, the author relates, by the 'engineering genius', andrew ritchie, in 1975. its existence is predominantly at the behest of ritchie's dislike of the ride quality of the bickerton folding bike, one which he thought he could improve. i confess that many years ago, i received a brompton for review, a bicycle which arrived folded within a cardboard box. it does me no favours to admit that, after spending 45 minutes attempting to unfold it, i'd to resort to youtube, a video which gave me the metaphorical slap on the face for being such an idiot.

until that point, every other folding bike i'd come across, folded in half laterally; the front half folded alongside the rear. the brompton however, due to its ingenious, andrew ritchie invented hinge, effectively folds beneath itself, the rear wheel assembly fitting into place beneath the curved 'top tube'. this allows brompton to attach two small wheels to the end of the rear rack, enabling it to be pulled along by the saddle, in the manner of many modern-day suitcases.

the author, it transpires, is the current chief executive officer, a chartered engineer, who joined brompton from ici in 2002, and has overseen its progress from manufacturing almost 10,000 bikes per year until the present, when its output has almost reached ten times that number. at its manufacturing beginnings in 1995, the company employed 31; it now has a staff of 786, and a turnover of £105 million. even if you've never ridden or folded a brompton, those numbers alone are impressive.

but as with many 'genius' engineers, they're far better left alone to concentrate on what they do best and let others ensure that their genius can be turned into sales and subsequent profits. my grasp of economics is rudimentary, to say the least, but it doesn't take a hedge fund manager to comprehend the author's undoubted suitability for the position he currently holds. the fact that he too is an engineer no doubt aided and abetted the travails of a business in which many of the processes are carried out in-house.

as mr butler-adams relates, "The key problems to solve in a folding bike are rigidity and strength, and the easiest way to make something strong is to add more metal to the structure. Conversely, the easiest way to make a bike that weighs less, is to remove metal from it, and this will, other things being equal, make the structure weaker." rather obviously, a folding bike defines a specific purpose, one that will allow for portability both before and after any bike ride. but there's little point in that ease of carriage, if it rides like a noodle. and having outside contractors manufacture complex and individual parts for limited numbers of a unique piece of machinery could conceivably make its retail price too high to encourage sales figures that might offset the problem.

the author, by his own testimony, business acumen and apparent lack of ego, seems the perfect fit for the company, but also sufficiently aware to detail the beginnings of the brompton folding bike from the 1975 invention of that hinge, through the early days of start-stop manufacture, the not unexpected difficulties of acquiring sufficient finance and the inevitable upscaling and moving of premises, as the brompton's fortunes improved.

"This, then, is the story of the Brompton bicycle [...] It's told from a particular point of view - mine - and that means there are bound to be some biases and blind spots, but I've done my best to be honest and to consult other people who sometimes remembered things slightly differently."

the first part of mr butler-adams' narrative (the book is divided into complementary sections) is all about making bikes. "I'm going to spend some time discussing in detail things I learned about the manufacture of the Brompton bike during two decades in a factory."

describing the folding bike as "...a massive compromise...", he moves on to discuss the tolerances required to manufacture the brompton, the concept of the 'jigs' used to create consistency of output, having to acquire an expensive and bespoke cnc machine for in-house manufacture, and the importance of quality. and while early steel bicycles were joined together by means of cast lugs, the steel parts on a brompton are conjoined by fillet-brazing, a highly skilled task. the philosophy at brompton allows any employee in any department to check if they have the aptitude and skill to undertake this highly paid job.

but, as stated above, will butler-adams is the ceo of brompton, the skills for which are not necessarily the same as those required to physically build a bicycle. in a section entitled 'building a company' the author reiterates this fact by pointing out that "...a company has a lot more moving parts." this opening paragraph is faced by a copy of a letter from the design director of ti-raleigh, informing a previous brompton director, that they would not be opting to manufacture the folding bike on the basis that it was unlikely to sell in sufficient quantities to make it a commercial reality.

as ceo he seems keenly aware that, in order to progress the business to improved profitability "...everything has to change so that anything can stay the same." and that "It is not easy for anyone to be the second chief executive of a company founded by a genius." he details the various arrangements made internationally to secure profitable overseas distribution, and how brompton eventually brought/bought many of these back under their own jurisdiction to retain the control he was sure they needed to progress in a profitable manner

butler-adams also possesses a perspicacity that often seems rare in modern manufacturing and business administration, keenly aware of the brompton's ability to change lives for the better within inner-city and urban environments, but without resorting to extraneous attempts to become fashionable. reprising the historical change from the horse to the motor car he points out that the over 50% of the world's population who live in cities account not only for 80% of the planet's economic output, but 60% of its greenhouse gases. if, as forecast, the population of the world's cities continues to increase, the means by which that population moves about, is unlikely to be solved by electric cars.

this chapter also includes the classic image of 42 folded bromptons occupying a single car parking space.

and having broached the subject of electric transport, he moves on to detail the almost tortuous history of bringing an electric brompton to market. while many ordinary e-bike manufacturers are content to simply add a motor and battery to an existing frame design, the brompton is a substantially different challenge due to the overarching requirement for portability. in other words, there's little point in electrifying the brompton if its owners would have to enrol in a body-building course to be able to lift it.

"At times we toyed with the idea of taking one of these motors and putting it onto a Brompton anyway, just so that we were in the game, but only bodybuilders or rugby players would be able to carry one."

if i could think of a legitimate reason to own a brompton, i'd have one in a heartbeat. it may be a bicycle that offers nothing other than the function for which it was designed, but that's not to say its form-factor is not intriguing and extremely pleasing to the eye. nor indeed that the 'nothing' isn't a major substantiality in and of itself. having ridden bromptons on more than a single occasion, i can testify to their sense of fun, and even their suitability for the rural landscape, even if the folding part would be a feature little used this far west. this book has only increased that desire. while it admittedly deals with engineering concepts and business practices, the narrative is compulsive (i completed reading in a little over four hours) and well worth £25 of anyone's money. even more so if you own or are a prospective owner of a brompton bicycle.

they really ought to include a copy with every brompton sold.

monday 19 december 2022

..........................................................................................................................................................................................................

..........................................................................................................................................................................................................